Built-Up Roofing

In recent years built-up roofing (BUR) has largely become a legacy product. The reasons vary in importance, but largely include safety, the lower availability of trained installation personnel, concerns over modern material durability, the high expense of BUR and the relative improvements in other roof systems.

The coal tar pitch variation of BUR has become nearly unheard of for new installations in recent years.

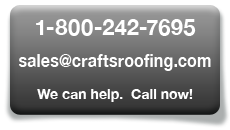

While Crafts Inc no longer actively pursues BUR projects, we are able to service, alter and maintain asphalt and cold tar pitch BUR roofs.

The following information on BUR is provided so those who have never seen a BUR have some explaination what this legacy product involved.

-

Provide multiple layers of protection

-

More rigid and stable surface

-

Increased thermal performance

-

Increased uplift performance

-

Highest of fire ratings available

-

Can be coated for reflectivity

Crafts Inc. has been installing built-up roofs (BUR) for over 50 years. These roof systems are commonly referred to as "tar and gravel" roofs. BUR systems generally are composed of alternating layers of bitumen and reinforcing fabrics that create a finished membrane. The number of plies in a cross section is the number of plies on a roof. The reinforcing fabrics are also called roofing felts or ply sheets. Roofing felts are reinforced with either glass-fiber mats or organic mats.

The bitumen typically used in BUR roof systems is asphalt, coal tar or cold-applied adhesive. The asphalt or coal tar is heated in a kettle or tanker and then applied by mop or mechanical spreader.

Surfacing for built up roof systems include aggregate (such as gravel, slag or mineral granules), glass-fiber or mineral surfaced cap sheets, hot asphalt mopped over the entire surface, aluminum coatings or elastomeric coatings.